It takes two years to lose industrial knowledge (know-how) but can take twenty years to rebuild it, whether it is to make fine silk or fine cars

Know-how is different from scientific knowledge, and anyone who has read a an economics text budget knows that, for example, the commitment to the creation of a patent is less than 20% of that for its transformation into an industrial product.

For this reason, there is a marked difference between university and industry and it is difficult to make them work together and understand each other. Each one overestimates its importance while diminishing the value of the other, to the point that each side attempts to do the work of the other and results do not come.

The history of silk in Italy has followed a similar path. Unless you are a silkworm, to make silk is not a simple task, and to convert that natural filament into a silk thread for weaving is especially challenging if the ambition is to make silk to compete in the high value markets of elegance and luxury.

Italy had been for years a leader in the production of fine fabrics, silk velvet brocade was the "oil" of the Republic of Venice. Then, forty years ago, the mills have stopped to make silk and the last silk mill has been used only as an example of industrial archeology - until the arrival of Salvatore Gulli.

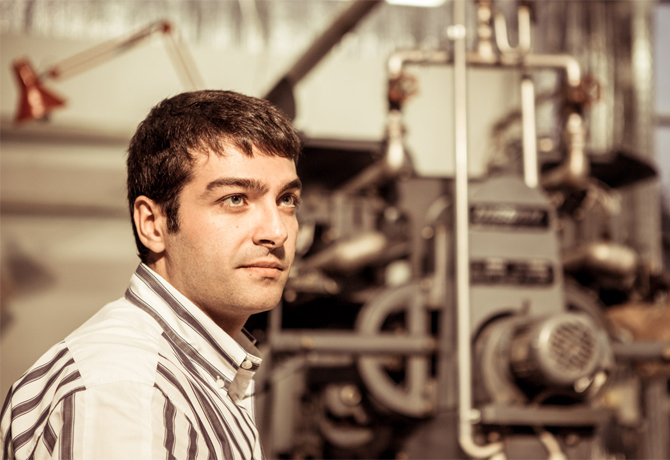

Salvatore comes from Sicily and fell in love with silk during a school tour. Then he chose automation engineering at university, with the dream of working in a textile mill to make silk. No one could teach him the industrial know-how and seven months after graduation he went to Japan to regain understanding of the technology.

Salvatore, how was your experience in Japan?

Very interesting, I learned a lot of essential practical techniques to make silk, both for the hands and the machines and I know that the path to perfection will not be easy and quick, but the road will be exciting and I think we can get back to creating top quality silk in Italy.

In some moments the meeting with Japanese culture has been traumatic, I was not familiar with language and ritual gestures, but its technology to make silk is among the best and it was the only way to understand the spinning mills.

What are you working on now?

With the goldsmith company D'Orica, the support of the CRA of Padua and Energitismo we have put into operation a spinning mill with Italian cocoons.

The idea is to make silk and gold jewelry by combining the Dorica fine gold spheroids with 100% Italian silk, and to present them in January at Fiera di Vicenza in VicenzaOro, one of the most important fairs in the gold sector.

Do you think that you can get back to producing silk in Italy in an industrial way?

I must admit that I did not imagine the interest that has arisen around the first silk we worked and, hearing the comments and letters of request for information that I receive, I think there is a great desire to return to complete the entire production cycle to make silk. Starting from mulberry cultivation, to silkworm breeding and cocoons production, to weaving and to final processes, where Italy still plays a leading role in the international scene.

For those who want more information I suggest you contact the CRA of Padua or Energitismo for guidance on what are the first steps to take to start a business to make silk.

Follow us